Cut Through Manufacturing Complexity - Reduce Waste, Boost Output

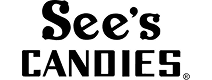

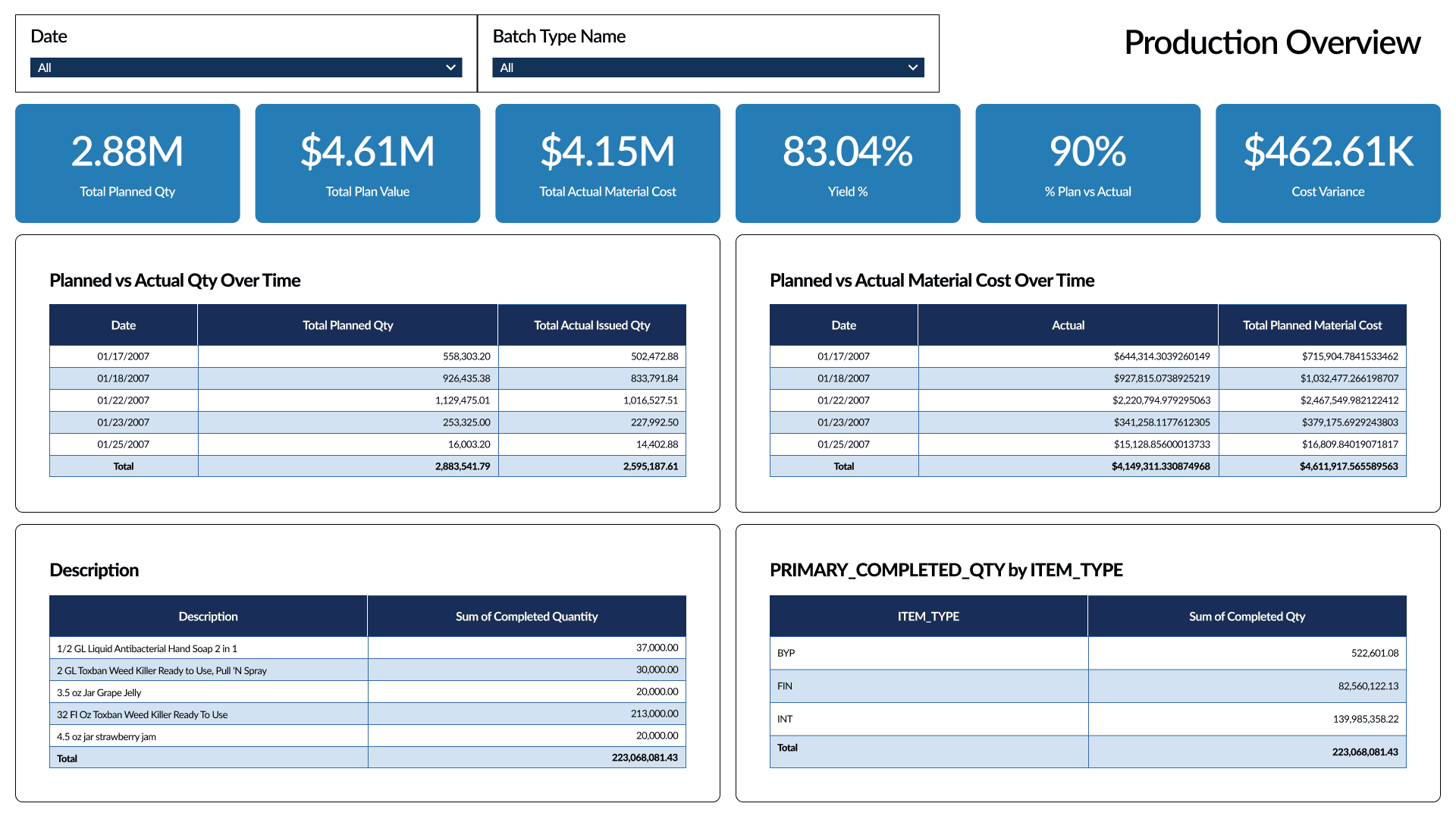

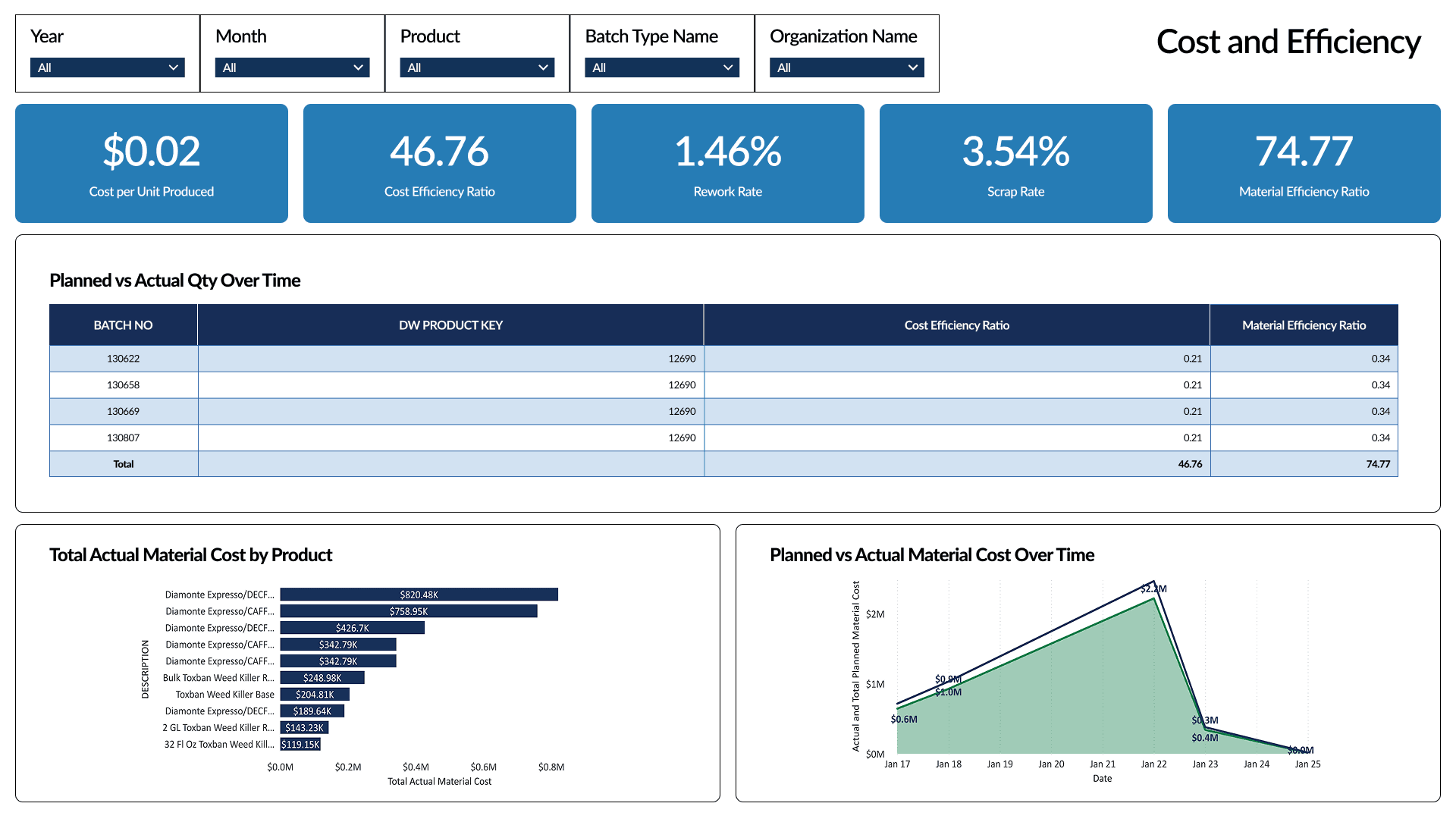

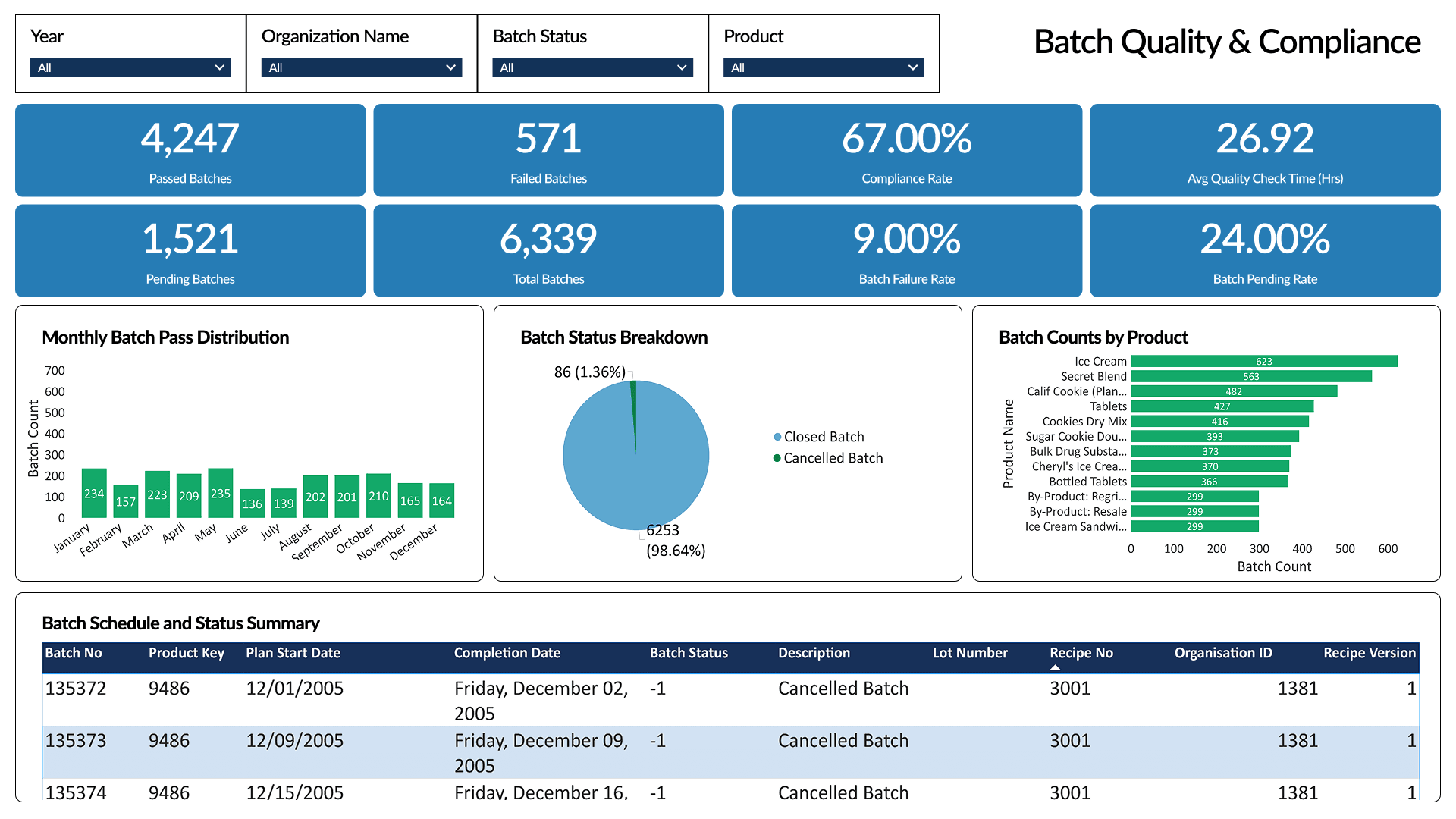

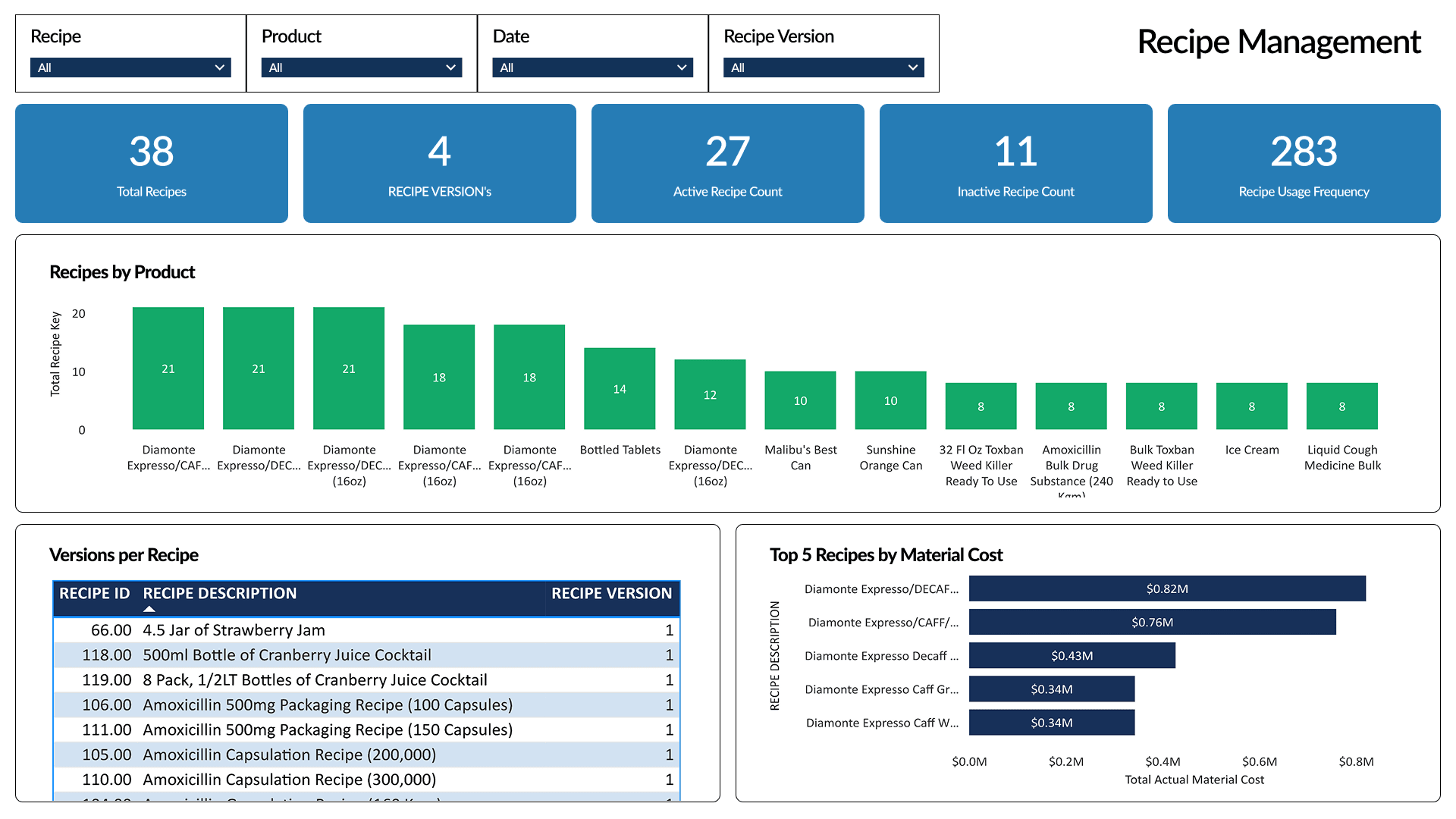

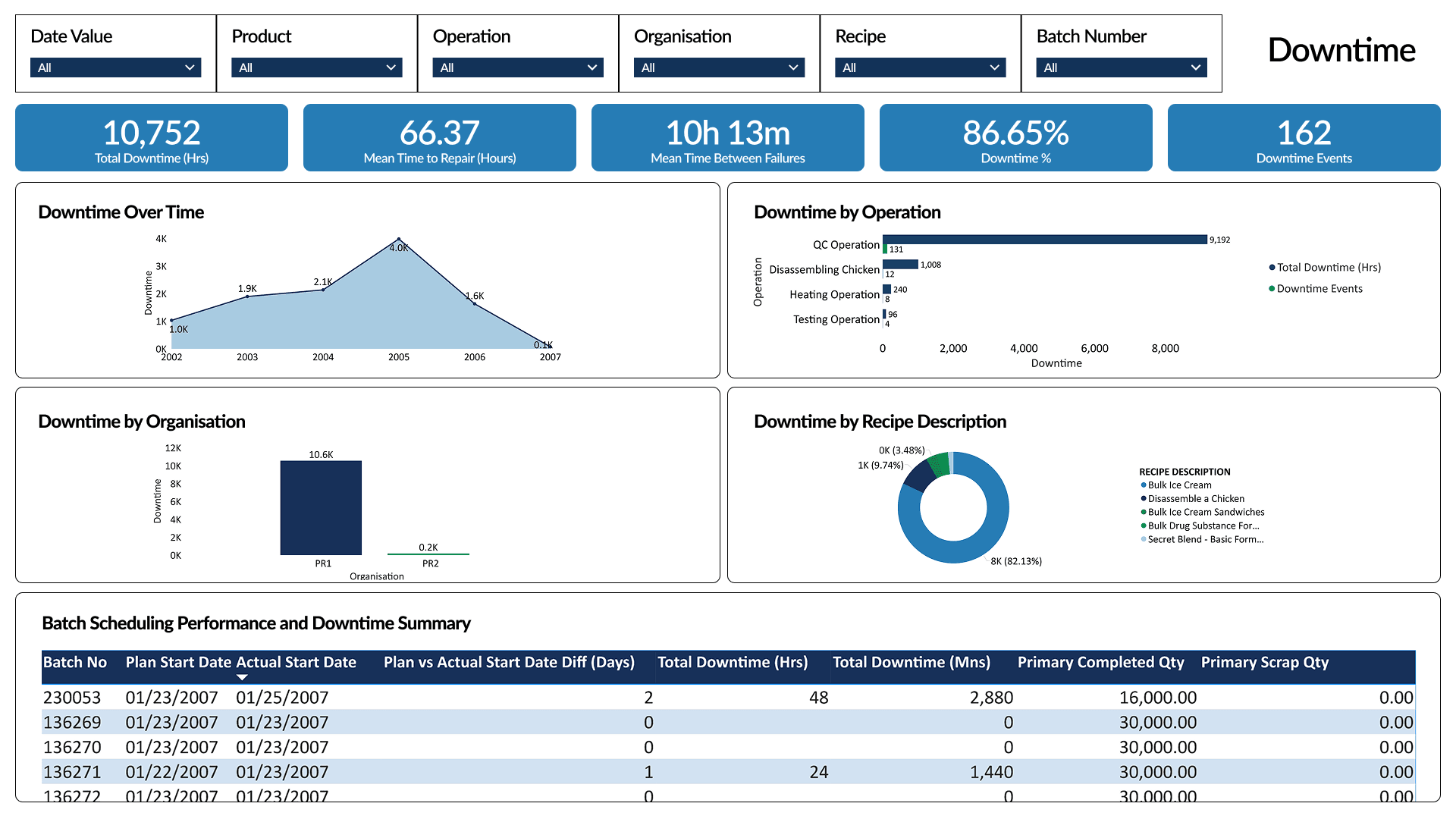

DiLytics Manufacturing Insight Solution uncovers hidden losses in your production process, from material over-consumption to batch cycle delays and unplanned downtime. Get AI-powered visibility into what's slowing you down and what's costing you money.

Take Control of Your Operations!

The Agility Gap

The Hidden Cost of Slow Answers: How Data Delays Are Killing Manufacturing Performance

Manufacturing leaders face a frustrating paradox: they're drowning in numbers but starving for insight. When a critical question arises - Why did material costs spike? Which operations are dragging down efficiency? Where is unplanned downtime really coming from? - the answers are buried across disconnected systems, locked in static reports, or dependent on analysts who are already backlogged. This insight gap doesn't just slow decision-making; it fundamentally limits your ability to compete. While your data sits idle, your competitors who can act on insights faster are optimizing yields, reducing waste, and capturing margins.

Let's Talk!Trusted Manufacturing Analytics, Ready to Deploy

DiLytics Manufacturing Insight Solution is a prebuilt analytics solution that provides insights and foresights into various manufacturing related aspects that help Manufacturing teams to make data-driven decisions, improve work efficiency and contribute to the success of the organization. It empowers production teams, plant managers, and supply chain leaders to make data-driven decisions that enhance process efficiency, reduce downtime, optimize resource utilization, and ensure consistent product quality - all contributing to the overall operational excellence of the organization.

Content

Verified

Powered

By Design

Enabled

Solution

Analytics

Foresights

Deployment

Implementation

Get Instant Answers to Your Questions.

Compatible with Multiple Data Platforms

Request Our Manufacturing Insight Solution Demo

Drive Cost Savings and Operational Efficiency

Experience actionable manufacturing insights tailored to your operation. Complete the form to connect with a DiLytics specialist and receive a personalized demonstration of how our solution can reduce downtime, optimize output, and improve decision-making across your plant. See how leading manufacturers transform data into measurable results - start your journey with DiLytics today.