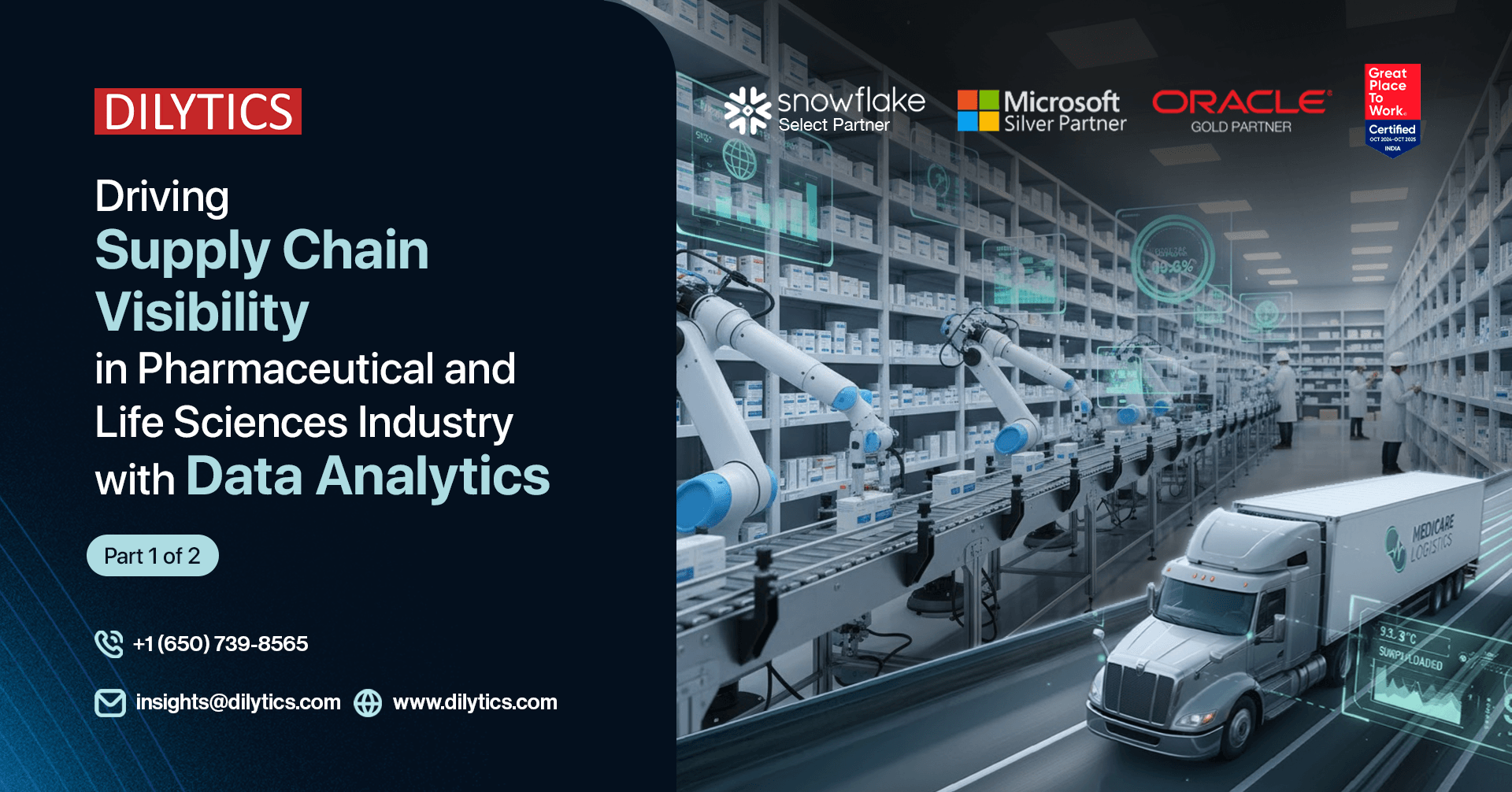

The pharmaceutical and life sciences supply chain has undergone enormous changes over the last couple of centuries. And with each change, the extent of complexity has increasingly become more.

In the 19th century, the supply chain was very localized – products were manufactured and consumed in a very small geographical area. In the beginning of the 20th century, globalization and advancements in transportation and storage allowed companies to distribute products over a much larger geographical area. With this change came new challenges such as longer lead times, increased risk of delays, and greater exposure to geopolitical disruptions.

In the mid-20th century, agencies like the U.S. Food and Drug Administration and the European Medicines Agency brought sharp focus on regulatory compliance and quality control. As a result, Good Manufacturing Practices and Good Distribution Practices were established, which brought in increased transparency and control over the movement of products. This added complexity and cost to the supply chain, as companies had to make investments in infrastructure upgrades to meet regulatory compliance.

In more recent times, outsourcing and offshoring of manufacturing to low-cost countries in the Asian region has introduced increased lead times, more dependency on external suppliers, and higher exposure to geopolitical tensions. Additionally, disruptions such as natural disasters, pandemics, or port delays in supplier regions now have a more pronounced ripple effect across a globalized supply chain.

With all these changes, the supply chain function in pharmaceutical and life sciences companies currently faces the following pressing challenges:

- High drug approval timelines (12-18 months)

- Surge in raw material cost (~22% since 2022)

- Talent gap in digital logistics and advanced therapy production areas

- Significant annual loss (~$35 billion) due to temperature-related issues

- Waste of ~$8 billion worth of biologics every year due to customer delays

Amidst this scenario, the ability to track, monitor, and analyze the data throughout the supply chain – from supplying raw materials to manufacturing, distribution, and final delivery to hospitals, pharmacies, or patients – has become a key need for pharmaceutical and life sciences companies to tackle these challenges. This ability, called ‘Supply Chain Visibility,’ helps companies get a real-time, end-to-end view of their supply chain network.

In this blog, we will discuss the role of data analytics in providing ‘Supply Chain Visibility’ to pharmaceutical and life sciences companies.

Two Segments of Supply Chain

The supply chain ecosystem can broadly be divided into two interdependent yet distinct segments: The first segment is ‘supply chain planning,’ which deals with identifying the actions that need to be taken to establish an efficient and effective supply chain. The second segment is ‘supply chain execution’ which deals with actual execution of the steps identified during ‘supply chain planning’ stage.

This blog is in a two-part series. In this (1st part) part, we’ll explore the role of data analytics in driving visibility in ‘supply chain planning’ segment. In the next blog, we’ll focus on how data analytics drives visibility across ‘supply chain execution’ segment.

Technologies Driving Supply Chain Visibility

Several technology solutions are crucial for enabling robust supply chain visibility in the pharmaceutical and life sciences industry. These technologies work in concert to provide real-time data, enhance decision-making, and improve overall supply chain performance. The top five technology solutions include:

- Track and Trace Systems: These systems utilize technologies like serialization, radio frequency identification, and barcode scanning to track products throughout the supply chain.

- Internet of Things Devices: Sensors and devices embedded in packaging and transportation units monitor critical environmental factors such as temperature, humidity, and location, ensuring product integrity, especially for temperature-sensitive pharmaceuticals.

- Cloud-Based Platforms: Cloud computing provides a centralized platform for data storage, processing, and sharing, enabling real-time collaboration and access to information across the supply chain.

- Blockchain Technology: Blockchain enhances transparency and security by creating an immutable record of transactions, improving traceability and combating counterfeiting.

- Data Analytics: Data analytics leverages advanced algorithms and machine learning to analyze the vast amounts of data generated by the other technologies. This analysis provides actionable insights into supply chain performance, identifies potential risks and inefficiencies, and supports data-driven decision-making for optimized operations and improved resilience.

Among the above-mentioned technologies, data analytics acts as the intelligence layer – interpreting signals from IoT devices, identifying patterns across cloud supply chain management platforms, informing AI models, and validating blockchain records. In doing so, it augments supply chain visibility by acting as the backbone that integrates data from various sources and provides a single source of truth across the entire supply chain.

Role of Data Analytics in Driving Visibility in Supply Chain Planning

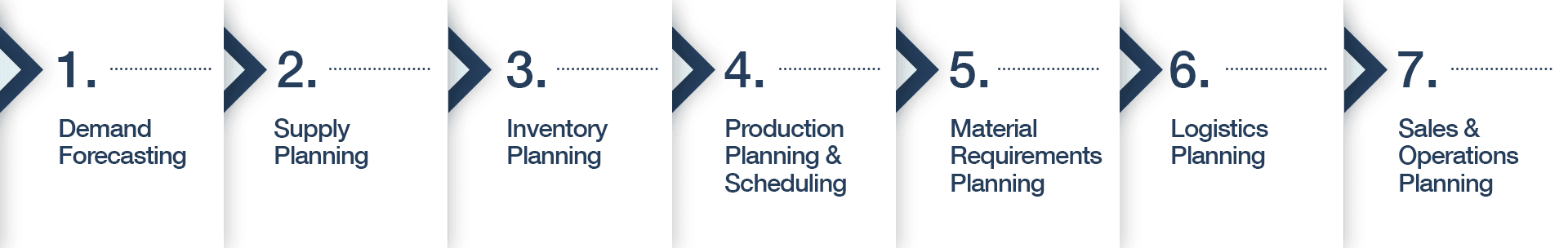

Supply chain planning focuses on the following areas:

1. Demand Forecasting

Demand forecasting is the process of understanding and predicting customer’s requirements for pharmaceutical products. This involves analyzing historical sales data, market trends, seasonality, promotional activities, and other relevant factors to estimate future demand. Accurate demand forecasting is crucial for ensuring that the right amount of product is available at the right time, minimizing stockouts and excess inventory.

However, most companies lack a unified view of data due to information residing in disparate systems – sales and order data in CRM systems, prescription and dispensing data in 3rd party data providers, inventory, production and procurement data from ERP, clinical trial data from clinical trial management system, etc. Further, the data used for forecasting is generally not of good quality and is not available at a lower level of granularity e.g. at SKU-level, for specific regions or individual pharmacies.

This leads to challenges such as stockouts and product shortages, overstocking and waste, suboptimal production planning, inaccurate budgeting, lost sales and market share and regulatory compliance risks.

This is where data analytics technology can play an important role in ways such as:

- Descriptive Analytics: Providing insights about historical sales, seasonality, competition, types of goods, and geography to understand past demand patterns, identify key demand drivers, and establish performance baselines.

- Diagnostic Analytics: Providing insights into why demand fluctuates to identify underlying drivers, reveal improvement opportunities, and support more accurate, data-driven demand planning decisions.

- Predictive Analytics: Forecasting future outcomes such as demand, demand fluctuations, new product launch, etc. to anticipate market trends, plan production and inventory proactively, and minimize stockouts or overstock situations.

- Prescriptive Analytics: Providing recommendations such as what pricing strategies to adopt, what promotional campaigns to carry out, what inventory levels to hold, etc. to optimize decision-making, maximize profitability, and enhance supply chain efficiency.

2. Supply Planning

Supply planning, also known as ‘sourcing’, involves identifying the most optimal suppliers for raw materials, active pharmaceutical ingredients, packaging materials, etc.; evaluating their capabilities; negotiating contracts with them; and managing relationships with them.

Most pharmaceutical and life sciences companies suffer from unavailability of real-time visibility into supplier capabilities and performance. This leads to increased risk of disruption, shortages, sub-optimal product quality, inefficient inventory management and reduced responsiveness.

Data analytics can play a significant role in addressing these gaps by:

- Descriptive Analytics: Providing information about historical supplier performance, lead times, and costs to understand past sourcing decisions and their impact.

- Diagnostic Analytics: Providing insights about reasons behind supplier delays, quality issues, or cost fluctuations to identify root causes of supply variability, improve supplier reliability, and enhance accuracy of supply forecasts.

- Predictive Analytics: Providing forecast about future supply availability, potential disruptions (due to geopolitical events, natural disasters, etc.), and supplier performance to mitigate risk, ensure supply continuity, and optimize sourcing and inventory strategies.

- Prescriptive Analytics: Providing recommendations such as what can be the most optimal sourcing strategies, who are the most suitable suppliers, and what contract terms can be favourably negotiated and how to improve procurement efficiency, reduce supply risks, and optimize cost.

3. Inventory Planning

Inventory planning is about determining the optimum requirement of stock of raw materials, work-in-progress, and finished goods to meet the demand as per demand forecast. This planning draws the fine balance between the opportunity cost of stock out and excess inventory holding cost (storage, obsolescence, and insurance).

Most pharmaceutical and life sciences companies face inventory planning challenges due to a variety of factors such as lack of availability of integrated data, inaccurate demand forecasting, limited real time tracking of goods at various stages of supply chain, inefficient management of suppliers, unoptimized warehouse operations, and inadequate risk planning.

Data analytics can address these challenges by:

- Descriptive Analytics: Providing insights about current inventory levels, turnover rates, storage costs, etc. to understand the current inventory position and identify areas for improvement.

- Diagnostic Analytics: Providing insights about the causes of inventory shortages, overstocking, or obsolescence to identify inefficiencies, improve inventory control, and enhance stock management effectiveness.

- Predictive Analytics: Providing forecasts of future inventory needs based on predicted demand, lead times, and supply chain constraints to enable proactive inventory planning, reduce inventory carrying costs, and minimize stockouts or excess inventory situations.

- Prescriptive Analytics: Providing recommendations about optimal inventory level to hold, reorder points, and safety stock levels to achieve the right balance between product availability and cost efficiency while improving overall supply chain responsiveness.

4. Production Planning & Scheduling

Production planning deals with ascertaining what to produce, how much to produce, when to produce, and how to produce. All this is done in alignment with demand forecast and available resources. Production scheduling deals with allocation of resources and sequencing of tasks to execute the production plan efficiently by minimizing downtime, bottlenecks, and delays.

In many pharmaceutical and life sciences companies, the various source system such as ERP, Manufacturing Execution System, Laboratory Information Management System are not integrated. Due to this, companies conduct manual calculations and spreadsheet-based production planning and scheduling. This results in challenges such as high production cost, high inventory cost, inefficient utilization of resources, slow responsiveness to demand changes, frequent stockout, high number of backorders, etc.

Data analytics can help companies overcome these challenges by:

- Descriptive Analytics: Providing visibility into KPIs such as on-time delivery, batch success rates, equipment utilization, inventory levels, etc. which help in pinpointing problems, evaluating performance against goals, and establishing a factual basis for effecting future improvements.

- Diagnostic Analytics: Identifying the root causes behind issues like batch failures, yield losses, production downtime etc. to improve manufacturing efficiency, enhance production reliability, and ensure consistent product quality.

- Predictive Analytics: Providing forecast about production bottlenecks, equipment availability, absenteeism or skill-based resource shortages, defects, energy consumption to enable proactive scheduling, optimal resource allocation, reduced downtime, and improved production efficiency.

- Prescriptive Analytics: Providing recommendations on optimal production sequencing, timing, and resource allocation to maximize throughput, minimize costs and energy use, and ensure timely, efficient fulfilment of production goals.

5. Material Requirements Planning

Material Requirement Planning (MRP) is the process of determining what materials are needed, how much of them are needed, when are they needed and where are they needed for manufacturing the final product. The main objective of MRP is to ensure that raw material is available for production in a timely manner without increasing the inventory carrying costs.

Many pharmaceutical and life sciences companies, especially the small and medium sized ones, resort to manual processes and usage of spreadsheets for MRP. Often data from different systems – Laboratory Information Management System, Manufacturing Execution System, Inventory Management System – does not come to MRP system due to lack of integration. Also, planners resort to manual overrides due to lack of trust in system-generated recommendations. These leads to challenges such as production delays, re-scheduling of production runs, reduced throughput, wasted labor and inefficient use of equipment.

Data analytics can help organizations alleviate these challenges by:

- Descriptive analytics: Providing insights about stock levels, supplier lead time variability, deviations from planned material usage which help in identifying instances of excessive inventory, frequent stockouts of specific materials, inaccurate BOMs, or delays from certain suppliers.

- Diagnostic analytics: Identifying root causes such as inconsistent supplier lead times, recurring raw material quality failures, inaccurate BOM data, or inefficient material handling to reduce material shortages, minimize expired inventory, and prevent production delays.

- Predictive analytics: Providing forecasts on supplier reliability, batch yield variability, material reorder points, safety stock levels, potential quality issues, etc. to enable proactive procurement planning, ensure material availability, and maintain consistent production flow.

- Prescriptive analytics: Providing recommendations on optimal order quantities, timing, safety stock levels, alternative suppliers, and backup logistics routes to minimize supply risks, control costs, maintain continuity, and ensure timely availability of materials for uninterrupted production.

6. Logistics Planning

Logistics planning deals with managing the movement, storage, and flow of materials and finished goods across the supply chain. This includes: 1) Inbound logistics – planning transportation and storage of raw materials and components from suppliers to manufacturing sites; 2) internal logistics – coordinating movement between manufacturing, packaging, and warehousing units; 3) outbound logistics – managing delivery of finished products to wholesalers, hospitals, pharmacies, and patients.

Many pharmaceutical and life sciences companies operate with fragmented IT systems for different logistics functions. Also, planning tasks related to route optimization, carrier selection and delivery schedules are often handled manually or with static rules. This leads to challenges such as stockouts at distribution points (pharmacies, hospitals, and distributors), increased product recalls due to compromised quality, high logistics costs, lost revenue from returned/wasted/expired products, fines and penalties for regulatory violations.

Data analytics can address these challenges by:

- Descriptive analytics: Providing insights into on-time delivery rates, transportation costs per route, warehouse space utilization, inventory turnover which help companies know about the inefficiencies in their distribution networks, identify underperforming carriers and peak periods for warehousing.

- Diagnostic analytics: Identifying root causes of issues such as temperature excursions, route inefficiencies, handling errors, or stockouts to enhance logistics reliability, improve cold chain compliance, and ensure consistent product availability across distribution channels.

- Predictive analytics: Providing forecasts on shipment delays, cold chain excursion risks, demand surges, warehouse constraints, and logistics bottlenecks to enable proactive mitigation, efficient capacity planning, and uninterrupted product distribution.

- Prescriptive analytics: Providing recommendations on optimal transportation routes, carrier selection, packaging configurations, shipping modes, and inventory reallocation strategies to minimize logistics costs, reduce transit risks, and ensure timely, compliant, and efficient product delivery.

7. Sales & Operations Planning

Sales and Operations Planning (S&OP) aligns demand forecasts, supply capabilities, inventory levels, and financial goals to ensure that a company can meet customer demand efficiently while optimizing inventory, resources, and costs.

Most pharmaceutical and life sciences companies’ systems landscape is fragmented – CRM for sales, ERP for finance, MES for production, LIMS for quality. Further, many rely heavily on manual processes and spreadsheets which limits their ability to do scenario planning and real-time adjustments. This leads to high inventory costs, inefficient capacity utilization, increased production and logistics costs, missed market opportunities, delayed and ineffective new product introduction and unreliable delivery.

Data analytics can address these challenged by:

- Descriptive analytics: Providing insights into forecast accuracy, demand variability, inventory turnover, order fulfilment, production plan adherence etc. that enable a unified S&OP performance view, identify process gaps, support alignment between demand, supply, and business objectives.

- Prescriptive analytics: Providing recommendations on optimal production schedules, regional inventory reallocation, and service level–working capital trade-offs to maximize operational efficiency, minimize costs, and ensure demand is met without overextending resources.

- Diagnostic analytics: Identifying root causes of S&OP misalignments such as forecast inaccuracies, capacity shortfalls, or supply constraints to enhance cross-functional visibility, improve plan reliability, and strengthen coordination between sales, production, and supply teams.

- Predictive analytics: Providing forecasts on demand surges, supply disruptions, material shortages, production bottlenecks, and market events to enable proactive planning, balanced supply-demand alignment, and timely decision-making in the S&OP process.

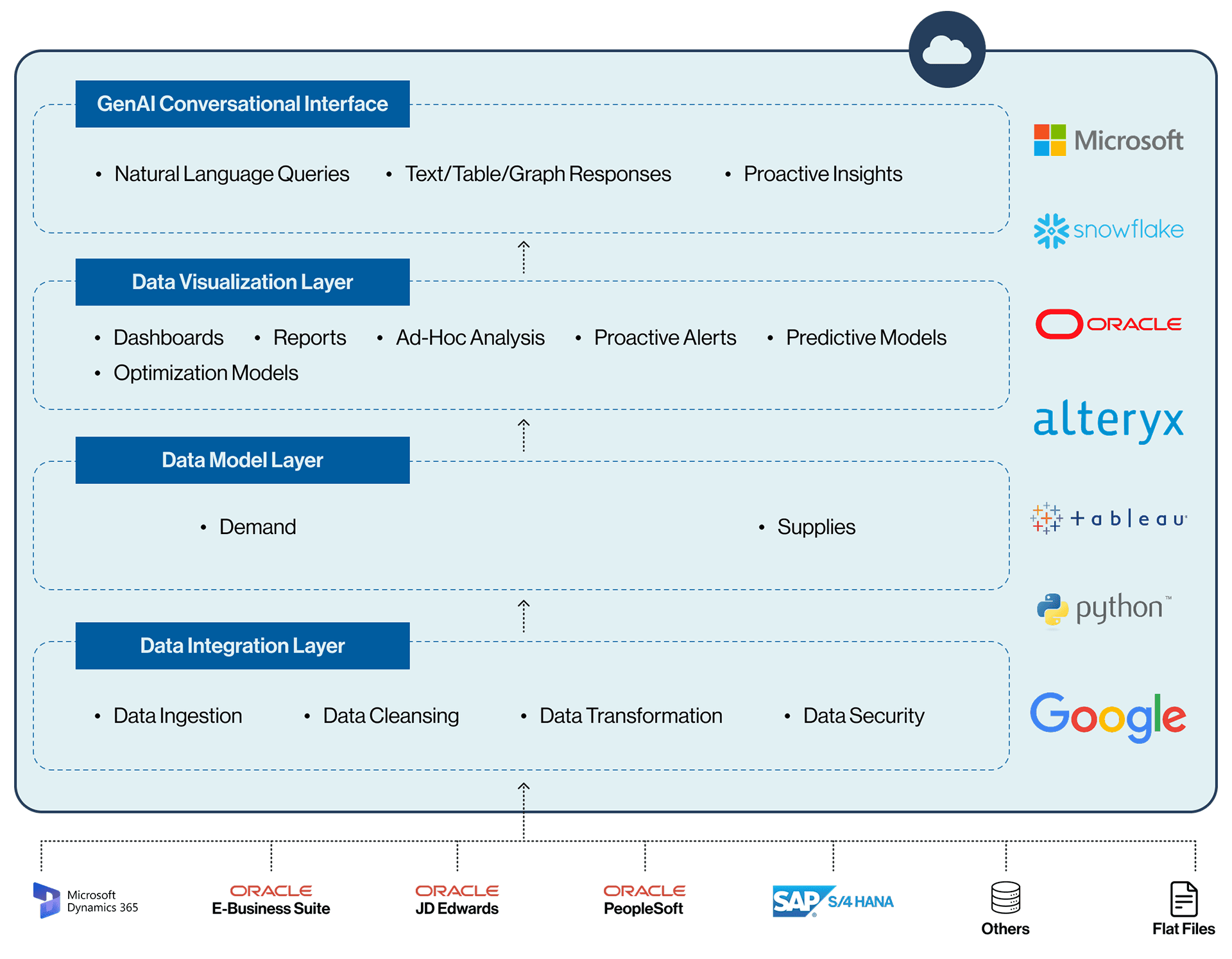

DiLytics Prebuilt Supply Chain Planning Insight Solution

DiLytics has built a supply chain planning solution, branded as DiLytics Supply Chain Planning Insight Solution, that provides the above-mentioned functionalities/capabilities for the pharmaceutical and life sciences industry. This solution comes with:

- Industry–leading data model

- Data pipelines from leading ERPs

- A rich library of reports, dashboards, and metrics

- Conversational interface

A high-level architecture of DiLytics Supply Chain Planning Insight Solution is provided below:

Conclusion

In the pharmaceutical and life sciences industry, where strict regulation, supply disruptions, and demand volatility are common, data analytics provides a potent mechanism to obtain end-to-end supply chain visibility. By breaking down data silos and leveraging advanced analytical techniques, companies can move from reacting to problems to predicting and preventing them. Leveraging these capabilities will empower companies to manage volatility better, minimize risks, reduce costs, and build a resilient supply chain. The future of the supply chain is data-driven, and visibility is at its core.